Photo courtesy of TCAT-Harriman.

When Free Medical Clinic of Oak Ridge executive director Billy Edmonds had an idea to host a New Year’s celebration event for the community, he asked the Tennessee College of Applied Technology (TCAT) at Harriman for help. Not long after, machine tool technology instructor Andrew Aydelott and the vice president of Tennessee College of Applied Technology (TCAT-Harriman) Chris Ayers found themselves collaborating with SkillsUSA students to build a ball drop for their December 31, 2023 celebration. The clinic provides free primary medical care for low-income or uninsured Tennessee residents and many of the school’s students use its services.

The challenge was accepted in March 2023 and the students in Aydelott’s machine tool class began planning for the 10-month project. “It was an ambitious project to begin with because it isn’t something that could be permanent. Most people don’t realize that the New York City ball is a permanent fixture on the building. They don’t take it down and put it up every year,” says Aydelott.

First, they held a brainstorming session with the machine tool class, several faculty members and the executive director of the clinic. Check out this video that shows the stages of planning:

“We decided to make the ball in the shape of an atom because of the city’s historical involvement in the Manhattan Project and the development of the first atomic bomb,” says Craig Heaton, a senior machine tool student. “To visualize how it would look, we used Autodesk Fusion360 to create 3D models and then created engineered drawings for the different parts to be fabricated. The outer rings were made of cold rolled steel and needed to be bent to a diameter of six feet within +/- .01 of an inch. After the structural items were manufactured, another student in the class tack welded them, and the ball was sent to the welding shop to be secured together.”

Next up were the lights. “We chose our bulbs and LED strips and calculated that about 1,900 lights would fit onto the ball,” says Trevor Massengale, a senior machine tool student. “We calculated the total power draw would be around 97 amps. To reduce the risk of loose connections and water or rain shorting it out, we soldered the inner ball lights connections and covered them using heat shrink tubing. We then added injection wires throughout the inner ball lights and soldered and powered the LED strips on the outer rings from both sides, so the lights could stay bright. We wanted to control the lights, so we divided the inner ball into three separately controlled sections and ran three separate wires to them and three other data wires to the LED strips. We also designed and 3D printed more than 1,000 clips to secure the lights in place.”

Teams of students then put on and secured the 864 clips for the center ball. They used small development boards to control the lights and ended up purchasing a professional board and modified it. “Once the lights were wired, we thought we could make it light up one solid color and then we could change the color,” says Joseph Griffin, a senior machine tool student. “Then, I found a program designed for Christmas lights and I programmed the ball to dance to the individual notes of the songs. It took an entire day to program just one song.”

Next, they needed to how they would drop the ball. Aydelott and Heaton, in collaboration with welding instructor Troy Hensley, designed and engineered a pole with a cantilevering arm to support the 150 lb. ball. The arm had to be portable, so the pole and base could be mounted on a flatbed truck and broken down in two pieces for transport.

The most important factor was safety during set up and the actual event. Due to the geometry of the truck bed and the weight of the pole, the lifting force needed was thousands of pounds. They tested multiple winches at various weight ratings before finally using a 9,500-pound winch to erect the pole. The overall height of the suspended ball was over 35 feet. They had to find another winch, only this time they weren’t concerned with how much it could lift but how fast the ball would drop. “We had to calculate the diameter of the wire on a spool because as the ball spool was unrolling, the ball would speed up, so the height of the pole and diameter of the spool had to be calculated so it would drop in exactly 30 seconds,” says Aydelott.

Troy Hensley asked his welding class to build a frame to mount it for transport and building construction technology instructor Charles Newport and his students built the trailer container to carry it in. The diameter of the ball was six feet.

“Each student in the machine tool technology program had a hand in the project,” says Aydelott. “According to data provided by the city, there were over 3,600 people that attended the event in person, with another 10,000 viewers online or watching on local TV, which streamed the event live.”

Aydelott overheard one student say the night of the event, “Well, I may not ever get to see New York’s ball drop, but by golly, I’m going to watch this one tonight.” Here is the ball just before the drop.

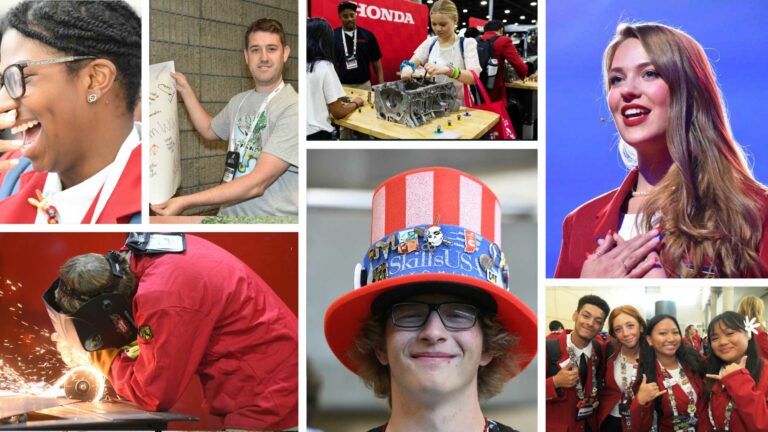

Heaton, Massengale and Griffith chronicled their class efforts and submitted them to the SkillsUSA Tennessee State Leadership & Skills Conference. The result? A gold medal in the Career Pathways, Industrial and Engineering Technology competition and a trip to Atlanta to compete in the SkillsUSA Championships in June. There is a saying that anywhere the struggle is great, the level of ingenuity and inventiveness is high. In this case, it was sky high — and ready to drop at the stroke of midnight!